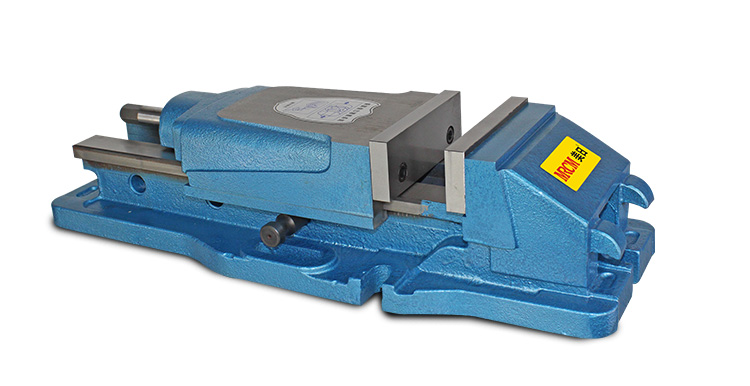

built-in vise

Built-in double vise, is the use of mechanical power structure, no need to refueling can easily lock a machine tool accessories. Vise sliding surface and the bottom, after precision grinding, parallelism precision, vise body using ductile iron FCD60 manufacturing, strong tensile strength, high wear resistance, easy to deformation. Vise sliding surface heat treatment HRC45 & deg; above, to maintain long-term wear and precision. Most suitable for ordinary milling machine, CNC milling machine, machining, mold manufacturing industry use.

[vise features]

1. As long as the hand of a shot, in turn on the two laps on the tons of clamping force.

2. vise Our use of high ductility cast iron to prevent deformation.

3. The pressure system with a small force, you can play a strong clamping force.

4. Three clamping range design, can be quickly deformed and easy to operate.

5. Built-in double-power booster for general milling machine, CNC vertical integrated machining center, the maximum opening can be caught 300mm.

[Note]

(1) When clamping the workpiece to be appropriate, can only use the hand plate tight handle, not with other tools afterburner.

(2) strong operation, should try to force the fixed body.

(3) Do not hit the job on the jaw and smooth plane.

(4) on the screw, nut and other activities should be regularly cleaned surface, lubrication, to prevent rust.

Basic parameters:

& nbsp;

built-in precision hydraulic vise

Built-in precision hydraulic vise: high power all-round precision hydraulic vise, suitable for general milling machine, CNC vertical integrated processing machine, the largest opening Can be clamped 300mm.

[Product Benefits]

1. Can be used alone or in multiple units.

2. As long as the hand of a shot, turn in the circle on the two tons of clamping force.

3. Strong and powerful material ~ Velvet body using high tensile tensile graphite cast iron (FCD60 ~ 60kgs / mm). (80,000psi) strong tensile strength, high wear resistance, easy to deformation.

Sponge sliding surface are hardening heat treatment HRC45 degrees or more, and by precision grinding, can maintain long-term wear resistance and accuracy. 4.

corner solid / external precision hydraulic vise

Corner-type / external-type precision hydraulic vise: high-power full range of precision hydraulic vise, suitable for general milling machine, CNC vertical integrated processing machine, the maximum opening can be caught 300mm.

[Product Benefits]

1 can be used alone or in multiple units.

2 angle solid semi-circular ball can produce the power of the corner lock - can eliminate the tiger's mouth floating and workpiece tilt.

3 strong and powerful material ~ velvet body using high tensile tensile graphite cast iron (FCD60 ~ 60kgs / mm). (80,000psi) strong tensile strength, high wear resistance, easy to deformation.

4 vise sliding surface are hardening heat treatment HRC45 degrees or more, and by precision grinding, can maintain long-term wear resistance and accuracy.